The Secret Revolution of Forklift Wheels: How a Green Tire Can Leverage the Hundred-Billion-Dollar ESG Market?

As the driving force behind industrial logistics, forklifts consume more energy and emit a carbon footprint far beyond imagination each year. However, as the global ESG movement sweeps across the manufacturing industry, a long-overlooked component — the forklift wheel — is quietly becoming a dark horse in the battle for carbon reduction.

I. An Underestimated Pioneer in Carbon Reduction: Reshaping the ESG Value of Forklift Wheels

1. Transformation of energy-consuming black holes

A diesel forklift produces an average of 5.6 tons of carbon dioxide annually, equivalent to the emissions of three family cars. Electric forklifts equipped with green tires can reduce CO2 emissions by 52%—and if powered by green electricity, emissions are nearly zero.

2. Benchmark of circular economy

Jungheinrich Group has achieved an 80% reduction in carbon emissions through industrial remanufacturing of forklifts: refurbishing a used forklift saves 4.2 tons of steel and reduces carbon emissions by 3.8 tons compared to manufacturing a new one. Linde China has developed a 100% recyclable forklift counterweight, embedding resource recycling into its product DNA.

3. Key levers for ESG ratings

The supply chain's carbon footprint accounts for 65%-90% of a company's total emissions. A polyurethane green forklift wheel's lifecycle carbon emissions are only one-third of those of a rubber wheel, directly helping companies achieve their Scope 3 emissions reduction targets.

II. Technological Breakthrough: From Material Revolution to Intelligent Empowerment

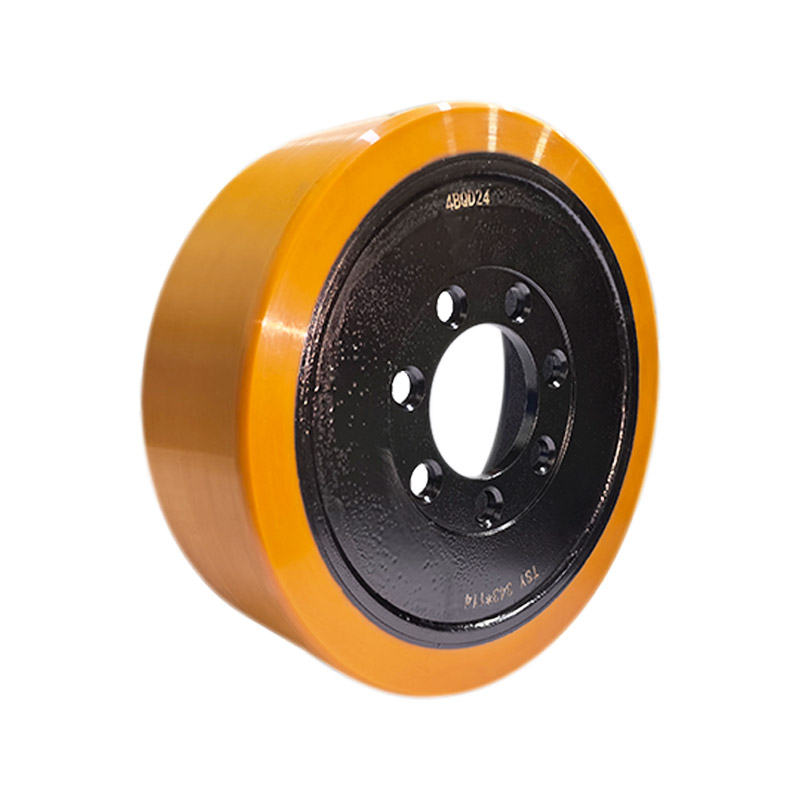

1. Green material breakthrough

Cobalt-free lithium batteries: Jungheinrich's patented battery technology eliminates the controversial raw material cobalt, achieving a win-win situation for both environmental protection and cost reduction from the source;

Special polyurethane formula: The tire has a wide temperature range, resistant to low temperatures of -40°C and high temperatures of 80°C, avoiding resource waste caused by frequent replacement;

2. Energy structure disruption

Linde China has deployed solar power stations at its factories in Zhangzhou and Xiamen, aiming to achieve full clean energy coverage at all production bases by 2024, and has fully electrified 50 service vehicles.

III. Carbon Ledger: Why are green tires the “conscience of making money”?

Take an auto parts factory as an example:

Traditional solution:

Traditional solution:

Green upgrade:

Green upgrade:

Green upgrade: Customized polyurethane oil-resistant tanker with a lifespan of 11 months, unit price ¥9,600 + zero downtime loss

→ annual cost ¥9,600

Save ¥226,000/year and reduce CO₂ emissions by 8.7 tons.

IV. The Future is Here: Three Disruptive Trends in Forklift Wheels

Bio-based materials: Polyurethane synthesized from soybean oil derivatives reduces carbon footprint by another 40%;

Blockchain traceability: The entire tire process from raw materials to scrapping is put on the chain to meet ESG disclosure audit requirements.

V. Corporate Action Guide

Gradient replacement: give priority to replacing tires of forklifts in high-load and high-temperature areas;

Policy arbitrage: Apply for green factory subsidies (such as Linde being rated as a national green factory).

A wheel, though small, is the fulcrum that leverages carbon neutrality in logistics. As ESG transitions from a buzzword to a cost imperative, green forklift wheels have evolved from an "optional" to a "must-have." In this green revolution driven by material innovation, circularity, and intelligent empowerment, domestically produced high-performance polyurethane forklift wheels, such as Skystone, are demonstrating strong competitiveness.

With their superior wear resistance, significant energy savings (effectively reducing rolling resistance), and resource conservation resulting from their exceptionally long service life, Skystone polyurethane wheels not only create significant economic benefits for users but also become a practical and efficient option for companies to achieve Scope 3 supply chain carbon reduction and fulfill their ESG commitments. Their excellent oil and temperature resistance (suitable for harsh operating conditions) and customized solutions further strengthen the position of green forklift wheels as a key lever for cost reduction, efficiency improvement, and sustainable development in the industrial logistics sector. In the future, with the integration of bio-based materials and blockchain traceability technologies, green forklift solutions centered around polyurethane wheels will become more deeply embedded in the core value chain of the trillion-dollar ESG market, accelerating the logistics sector's progress toward a zero-carbon future.

Copyright © 2025 Fujian Skystone Intelligent Equipment Co., Ltd. All Rights Reserved.

Network Supported

Network Supported