Heaviest Load & Duty Cycle - from advanced American polyurethane technology and revolutionary XL3™ bonding technology.

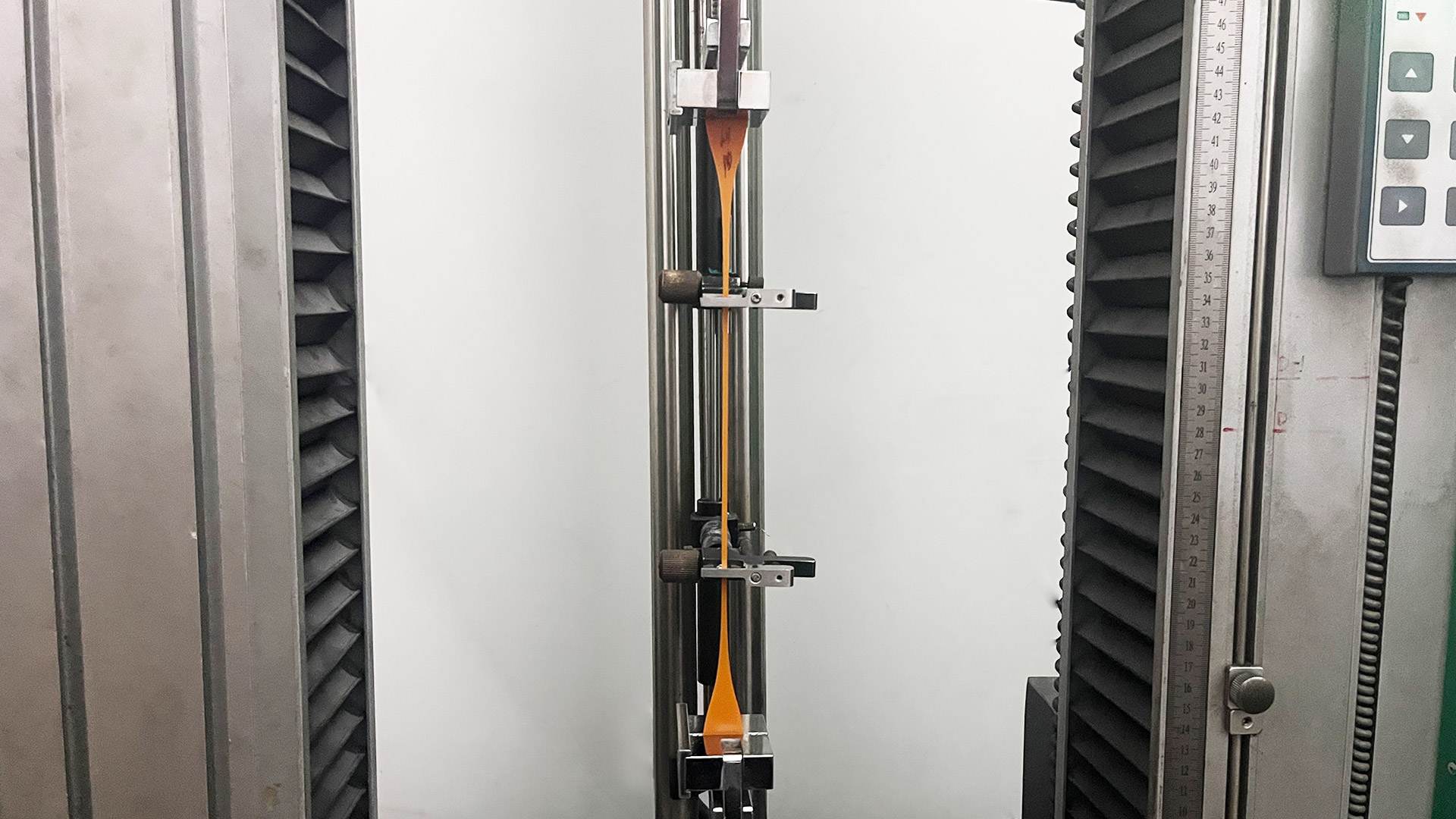

Defies the Worst Surface Conditions - from the toughest polyurethane compound with the highest cut & tear resistance.

No Bond Separation Guaranteed* - Proprietary XL3™ bonding agent and special steel surface finishing creates a bond that resists heat and shear force.

Code :

21070Z8Outer diameter(mm) :

210Wheel width(mm) :

70Hole diameter(mm) :

150Hole depth(mm) :

/wheel material :

PURim material :

castColour :

OrangeShore Hardness :

92 Shore A1-Features

Energy efficient compound provides easier rolling, capturing the full performance of AC-motor and extending battery life. The newest technology in polyurethane compounds that generates lower operating temperature in high speed warehouse applications is introducted.

2-Components

This goods doesn't Include load wheels w/bearings, axles, lube fittings, screws or roll pins Load. But all the above components are available according to your needs. wheel kits are Durarun Poly 92A which allows a high resistance for wear

Engineered for professionals who demand reliability, this steel Load Wheel delivers exceptional performance that extends equipment lifespan while reducing operational downtime.

3-Application scenarios and cases

1.Logistics warehousing: pallet handling, shelf storage and retrieval, improving product turnover efficiency

2.Industrial manufacturing: Material transportation on production lines, movement of heavy equipment, and adaptation to high-frequency operations

3.Special environment: chemical workshop (corrosion-resistant), cold storage (low-temperature resistant), food factory (clean and dust-free)

4-In-house factory · source manufacturing —— full process control from R&D to delivery production scale

5-Production workshop

Copyright © 2026 Fujian Skystone Intelligent Equipment Co., Ltd. All Rights Reserved.

Network Supported

Network Supported