The polyurethane forklift wheel and iron wheel centers are manufactured by our company, so that we can strictly control the whole process of production, and help reducing procurement costs for our customers. We have a group of talented designers who has rich experience in designing polyurethane solid wheels for different environments.

Code :

23090Z26Outer diameter(mm) :

230Wheel width(mm) :

90Hole diameter(mm) :

45Hole depth(mm) :

/wheel material :

PURim material :

CastColour :

OrangeShore Hardness :

92 Shore A

1-Features

Features

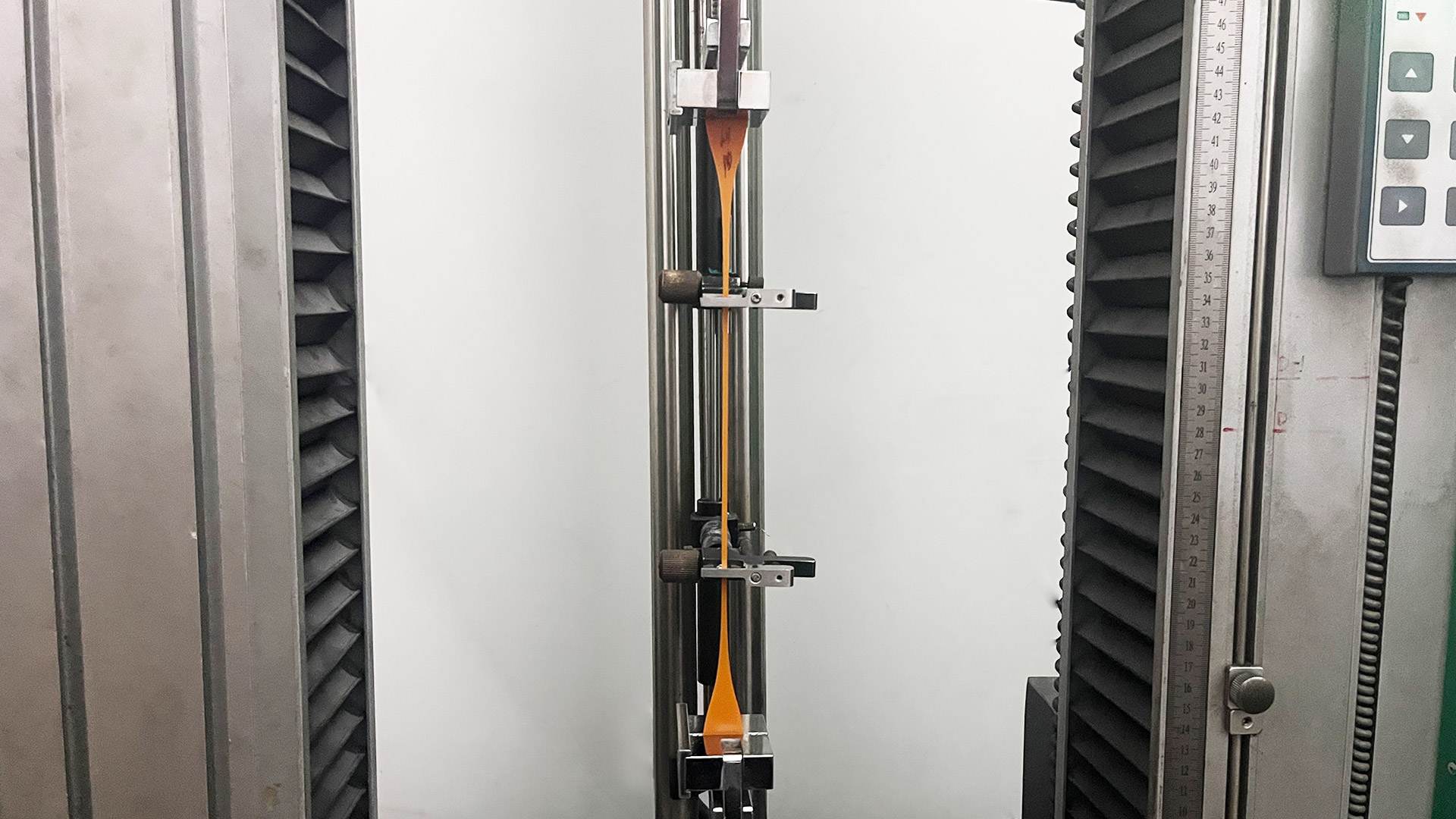

1. Each high quality PU wheel has a high resilience performance.

2. These wheels are known for their excellent wear resistance and small compression deformation.

3. When working in low temperatures (like in -40°C) or areas where the ground is frozen, the forklift truck is able to drive normally, thanks to these non-slip tires. Our polyurethane wheels for low temperature environments have been patented.

2-Technology

Heaviest Load & Duty Cycle - from advanced China polyurethane technology and revolutionary XL3™ bonding technology.

Defies the Worst Surface Conditions - from the toughest polyurethane compound with the highest cut & tear resistance.

No Bond Separation Guaranteed* - Proprietary XL3™ bonding agent and special steel surface finishing creates a bond that resists heat and shear force.

3-Application scenarios and cases

1.Logistics warehousing: pallet handling, shelf storage and retrieval, improving product turnover efficiency

2.Industrial manufacturing: Material transportation on production lines, movement of heavy equipment, and adaptation to high-frequency operations

3.Special environment: chemical workshop (corrosion-resistant), cold storage (low-temperature resistant), food factory (clean and dust-free)

4-In-house factory · source manufacturing —— full process control from R&D to delivery production scale

5-Production workshop

|

Linde Wheels |

Diameter,mm |

Height,mm |

Hole diameter,mm |

Depth.mm |

| Driving wheel | 400 | 160 | / | / |

| Driving wheel | 360 | 130 | 90 | / |

| Driving wheel | 350 | 100 | 68 | / |

| Driving wheel | 343 | 135 | 90 | / |

| Driving wheel | 343 | 114 | 90 | / |

| Driving wheel | 285 | 100 | / | / |

| Driving wheel | 254 | 102 | 80 | / |

| Driving wheel | 230 | 90 | / | / |

| Driving wheel | 230 | 90 | 48 | / |

| Driving wheel | 230 | 82 | 45 | / |

| Driving wheel | 230 | 75 | 45 | / |

| Driving wheel | 150 | 48 | 60 | / |

| Driving wheel | 140 | 50 | 20.5 | / |

| Driving wheel | 125 | 40 | / | / |

| Driving wheel | 125 | 26 | / | / |

| Balance wheel | 285 | 100 | / | / |

| Balance wheel | 140 | 55 | 47 | / |

| Balance wheel | 125 | 60 | 47 | / |

| Balance wheel | 125 | 40 | 35 | / |

| Balance wheel | 100 | 40 | 35 | / |

| Bearing wheel | 100 | 40 | 55 | 20.5 |

| Bearing wheel | 85 | 105 | 55 | 22 |

| Bearing wheel | 85 | 80 | 55 | 22 |

| Bearing wheel | 85 | 60 | 55 | 22 |

| Bearing wheel | 80 | 55 | 47 | 14 |

|

If you need other specifications, please contact us.

|

||||

Copyright © 2026 Fujian Skystone Intelligent Equipment Co., Ltd. All Rights Reserved.

Network Supported

Network Supported