Upgrade your material handling operations with our high-performance polyurethane forklift wheel, model 285x100-62.

Code :

285100Z40A24-2Outer diameter(mm) :

285Wheel width(mm) :

100Hole diameter(mm) :

62Hole depth(mm) :

42wheel material :

PURim material :

CastColour :

OrangeShore Hardness :

92 Shore A1-Features

Designed for durability and efficiency, this wheel is crafted from premium polyurethane (PU) that excels in demanding industrial environments. It offers exceptional wear resistance, reducing downtime and maintenance costs while ensuring smooth, quiet operation. The wheel's robust construction supports heavy loads and withstands exposure to oils, chemicals, and abrasive surfaces, making it ideal for warehouses, manufacturing facilities, and logistics centers.

Key features include a 285mm diameter, 100mm width, and 62mm bore for compatibility with various forklift models. Its non-marking design protects floors from damage, and the easy installation process minimizes disruption. Compared to traditional rubber or nylon wheels, our PU wheel provides better shock absorption, low rolling resistance, and a longer service life. This product is tested to meet international quality standards and comes with a warranty for added reliability.

2-Benefits:

Enhanced load capacity for improved productivity

Reduced noise levels for a comfortable work environment

Resistance to wear, tears, and harsh conditions

Cost-effective solution with minimal replacement needs

Ideal for use in pallet trucks, stackers, and other material handling equipment, this wheel helps optimize safety and performance. Choose our polyurethane forklift wheel for a reliable upgrade that boosts operational efficiency. Contact us today for more details or to place your order—we offer responsive support and fast shipping to meet your needs.

3-Application scenarios and cases

1.Logistics warehousing: pallet handling, shelf storage and retrieval, improving product turnover efficiency

2.Industrial manufacturing: Material transportation on production lines, movement of heavy equipment, and adaptation to high-frequency operations

3.Special environment: chemical workshop (corrosion-resistant), cold storage (low-temperature resistant), food factory (clean and dust-free)

4-In-house factory · source manufacturing —— full process control from R&D to delivery production scale

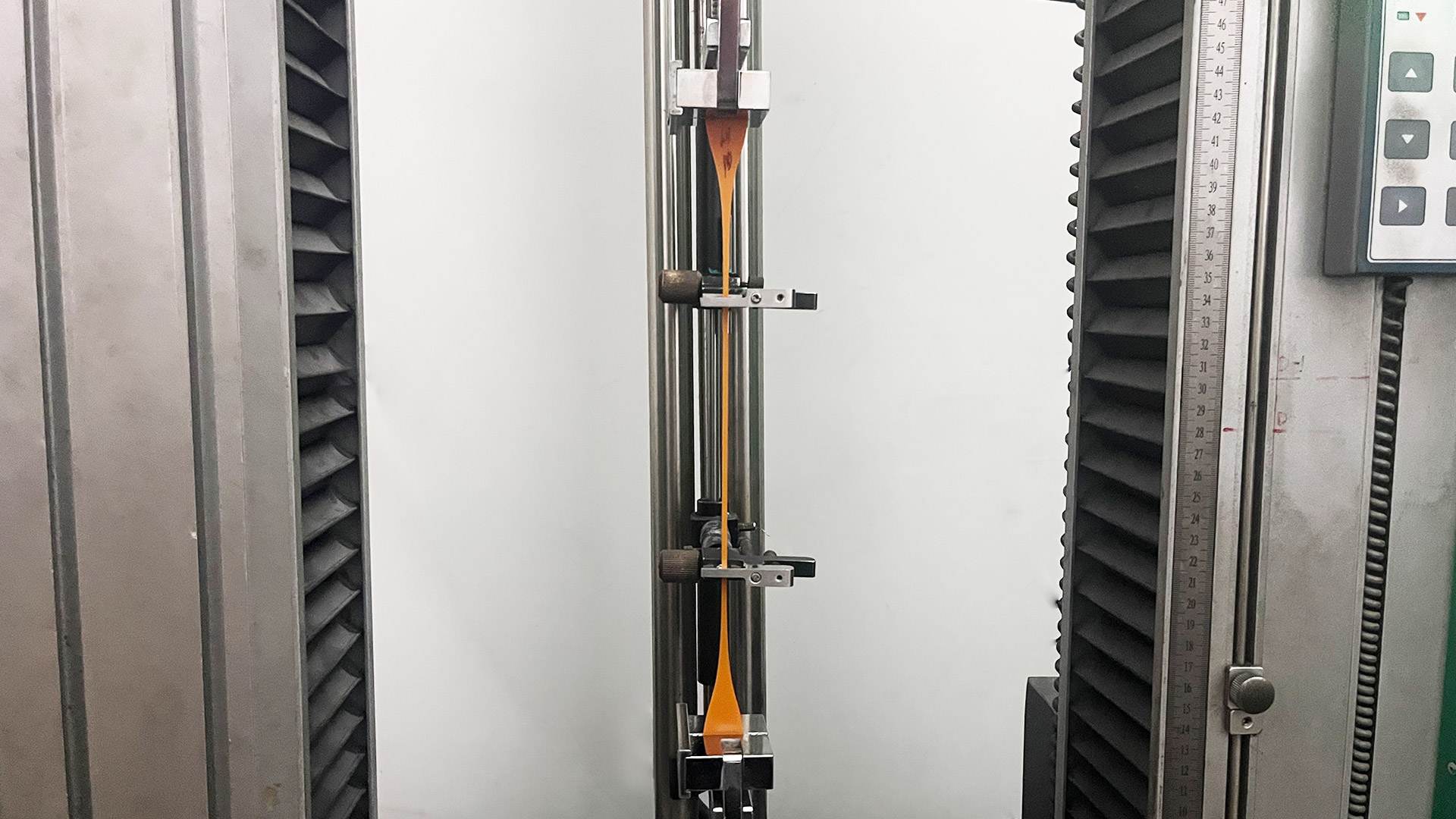

5-Production workshop

|

Linde Wheels |

Diameter,mm |

Height,mm |

Hole diameter,mm |

Depth.mm |

| Driving wheel | 400 | 160 | / | / |

| Driving wheel | 360 | 130 | 90 | / |

| Driving wheel | 350 | 100 | 68 | / |

| Driving wheel | 343 | 135 | 90 | / |

| Driving wheel | 343 | 114 | 90 | / |

| Driving wheel | 285 | 100 | / | / |

| Driving wheel | 254 | 102 | 80 | / |

| Driving wheel | 230 | 90 | / | / |

| Driving wheel | 230 | 90 | 48 | / |

| Driving wheel | 230 | 82 | 45 | / |

| Driving wheel | 230 | 75 | 45 | / |

| Driving wheel | 150 | 48 | 60 | / |

| Driving wheel | 140 | 50 | 20.5 | / |

| Driving wheel | 125 | 40 | / | / |

| Driving wheel | 125 | 26 | / | / |

| Balance wheel | 285 | 100 | / | / |

| Balance wheel | 140 | 55 | 47 | / |

| Balance wheel | 125 | 60 | 47 | / |

| Balance wheel | 125 | 40 | 35 | / |

| Balance wheel | 100 | 40 | 35 | / |

| Bearing wheel | 100 | 40 | 55 | 20.5 |

| Bearing wheel | 85 | 105 | 55 | 22 |

| Bearing wheel | 85 | 80 | 55 | 22 |

| Bearing wheel | 85 | 60 | 55 | 22 |

| Bearing wheel | 80 | 55 | 47 | 14 |

|

If you need other specifications, please contact us.

|

||||

Copyright © 2026 Fujian Skystone Intelligent Equipment Co., Ltd. All Rights Reserved.

Network Supported

Network Supported