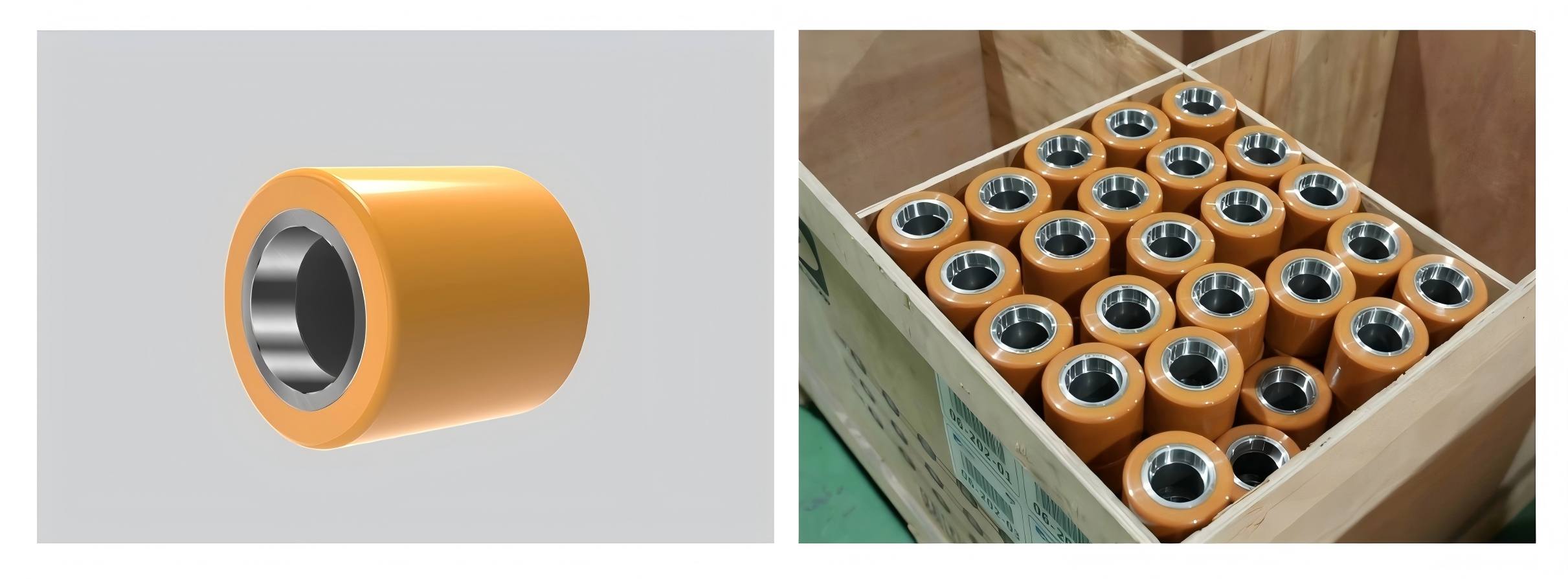

In today's rapidly developing logistics, warehousing and manufacturing industries, the performance of equipment parts directly affects the operational efficiency and cost control of enterprises. As a key component of industrial vehicles such as forklifts and AGVs (automatic guided vehicles), the choice of load-bearing wheels is undergoing a revolutionary change from traditional rubber to polyurethane (PU) materials. With its unique molecular structure and customizable properties, polyurethane load-bearing wheels are becoming the first choice of Fortune 500 companies.

Five core advantages of polyurethane load-bearing wheels:

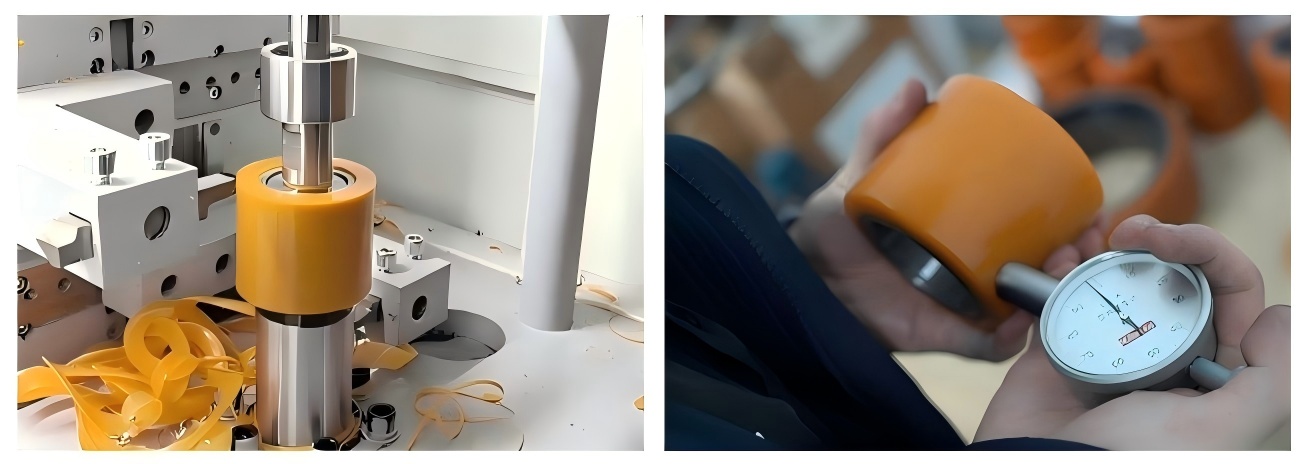

l Excellent physical properties: high tensile strength and tear resistance, low compression set and wear;

l Excellent dynamic performance: low energy loss and heat accumulation, high resilience;

l Unique micro-cellular structure: combined with high volume compressibility and minimal lateral expansion;

l Media resistance: able to withstand UV radiation, ozone and grease.

While providing high-quality polyurethane load-bearing wheels, Skystone Intelligent Equipment has been committed to the research and development of materials. Its R&D team led the production team through years of research and development and testing, and successfully developed exclusive polyurethane compounds. This high-performance new material is suitable for almost all types of industrial environments, especially the optimal solution for heavy-duty and high-speed applications.

Copyright © 2026 Fujian Skystone Intelligent Equipment Co., Ltd. All Rights Reserved.

Network Supported

Network Supported