Chinese factory wholesale 360*130 heavy-duty polyurethane forklift wheels

360*130 polyurethane wheels suitable for Linde forklifts, backed by years of production experience and mastery of core material production processes.

Code :

360130Z28Outer diameter(mm) :

360Wheel width(mm) :

130Hole diameter(mm) :

90Hole depth(mm) :

/wheel material :

PURim material :

CastColour :

OrangeShore Hardness :

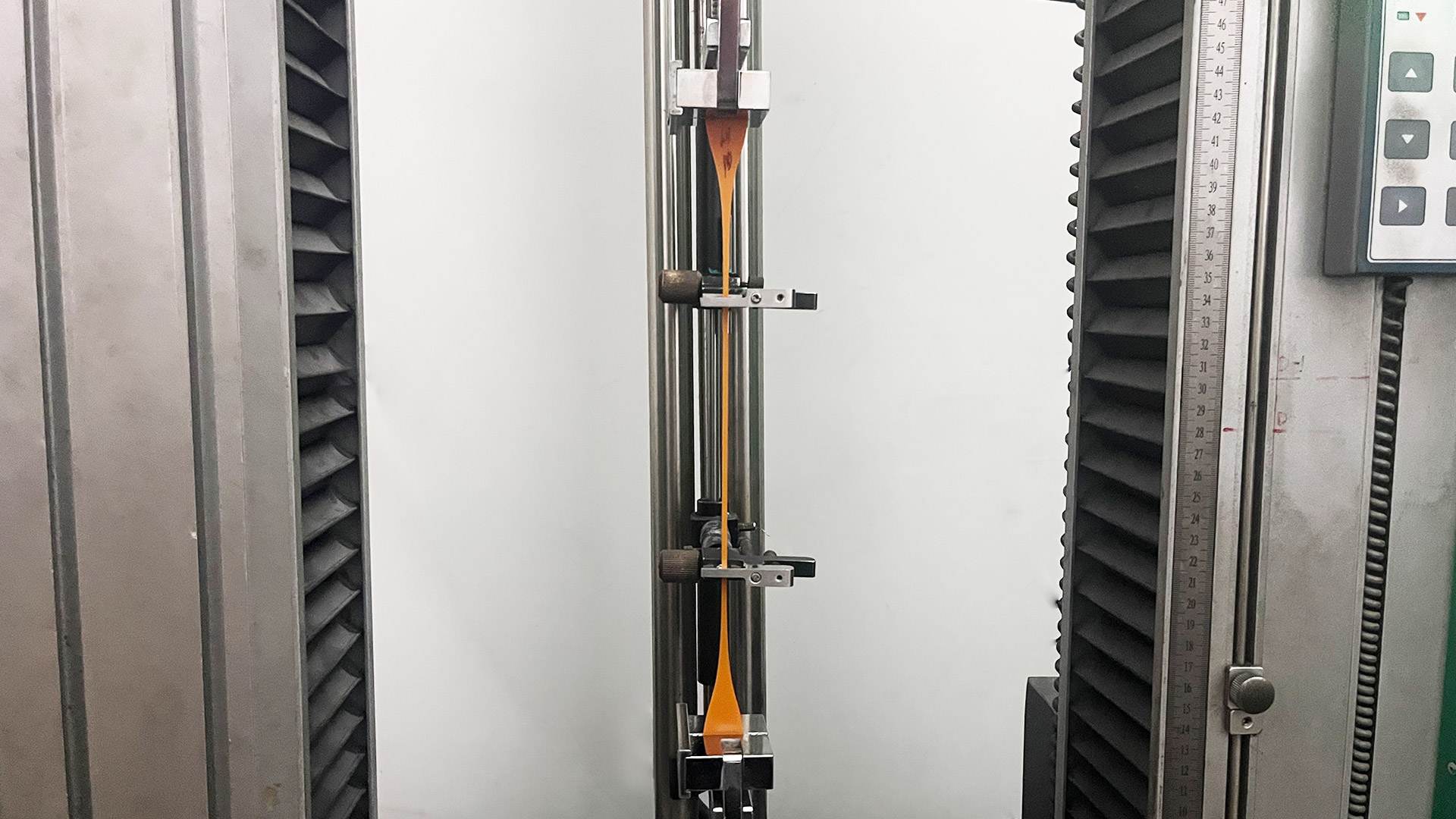

92 Shore APolyurethane drive wheels are primarily made of polyurethane elastomer, a material with numerous excellent physical and chemical properties. Polyurethane drive wheels are key components of electric forklifts, and their performance directly impacts the truck's operating efficiency and stability.

1-Core Features

1. Material Properties:

Abrasion Resistance: Polyurethane offers 3-5 times the wear resistance of rubber, especially in wet environments, significantly extending its service life.

Corrosion Resistance: Polyurethane offers excellent resistance to chemicals such as oils, acids, and alkalis, making it suitable for complex operating environments.

Low Noise: The resilience of polyurethane reduces friction between the tire and the ground, reducing noise pollution.

Shock Absorption and Noise Reduction: Its excellent elasticity effectively absorbs and disperses vibrations, enhancing operator comfort.

2. Structural Advantages:

Steel-core polyurethane integrated design: The steel core provides high-strength support, tightly wrapped with a polyurethane layer, forming a durable, integrated structure that ensures high load capacity and stability.

Modular Design: Easily install and replace, reducing maintenance costs.

2-Performance Advantages

1. Efficient Drive:

Low rolling resistance: Reduces energy consumption and improves the range of electric forklifts.

High Grip: The anti-slip texture design enhances friction with the ground, ensuring stable operation on wet or uneven surfaces.

2. Safety and Reliability:

Impact Resistance: High load capacity and impact resistance protect other forklift components from damage.

Anti-slip Design: The special pattern design enhances anti-slip performance and ensures safe operation.

3. Customization:

Hardness, specifications, and special features (such as anti-static and adsorption) can be customized to meet different environmental requirements.

3-Application Scenarios

1. Warehousing and Logistics:

Suitable for electric forklifts, stackers, and other equipment, meeting high-frequency, high-load handling needs.

2. Manufacturing:

Provides stable and efficient drive support for material handling on production lines.

3. Cold Chain Logistics:

Low-temperature resistance ensures excellent performance even in low-temperature environments.

4-In-house factory · source manufacturing —— full process control from R&D to delivery production scale

5-Production workshop

|

Linde Wheels |

Diameter,mm |

Height,mm |

Hole diameter,mm |

Depth.mm |

| Driving wheel | 400 | 160 | / | / |

| Driving wheel | 360 | 130 | 90 | / |

| Driving wheel | 350 | 100 | 68 | / |

| Driving wheel | 343 | 135 | 90 | / |

| Driving wheel | 343 | 114 | 90 | / |

| Driving wheel | 285 | 100 | / | / |

| Driving wheel | 254 | 102 | 80 | / |

| Driving wheel | 230 | 90 | / | / |

| Driving wheel | 230 | 90 | 48 | / |

| Driving wheel | 230 | 82 | 45 | / |

| Driving wheel | 230 | 75 | 45 | / |

| Driving wheel | 150 | 48 | 60 | / |

| Driving wheel | 140 | 50 | 20.5 | / |

| Driving wheel | 125 | 40 | / | / |

| Driving wheel | 125 | 26 | / | / |

| Balance wheel | 285 | 100 | / | / |

| Balance wheel | 140 | 55 | 47 | / |

| Balance wheel | 125 | 60 | 47 | / |

| Balance wheel | 125 | 40 | 35 | / |

| Balance wheel | 100 | 40 | 35 | / |

| Bearing wheel | 100 | 40 | 55 | 20.5 |

| Bearing wheel | 85 | 105 | 55 | 22 |

| Bearing wheel | 85 | 80 | 55 | 22 |

| Bearing wheel | 85 | 60 | 55 | 22 |

| Bearing wheel | 80 | 55 | 47 | 14 |

|

If you need other specifications, please contact us.

|

||||

Copyright © 2025 Fujian Skystone Intelligent Equipment Co., Ltd. All Rights Reserved.

Network Supported

Network Supported