Durable load-bearing wheels for Linde forklift parts, model 85x100

The Linde forklift-specific durable load wheel, Model 85x100, redefines the standards of reliability and efficiency with its exquisite craftsmanship, top-grade material selection, and exceptional performance.

Code :

85100G43B3DOuter diameter(mm) :

85Wheel width(mm) :

100Hole diameter(mm) :

55Hole depth(mm) :

13wheel material :

PURim material :

SteelColour :

OrangeShore Hardness :

92 Shore A1-Core Design and Exquisite Craftsmanship

The load-bearing wheels are manufactured in strict compliance with high-quality standards, ensuring seamless compatibility with your Linde forklift and optimal performance.

Precise Dimensions (85*100mm): These exact specifications guarantee perfect fitment with the frame and axle sleeve, facilitating easy installation. This eliminates abnormal wear, vibration, or noise caused by dimensional deviations, ensuring smooth and stable operation of the forklift.

High-Quality Material Selection: The wheels are made of high-strength, highly wear-resistant polyurethane (PU) material. Polyurethane is renowned for its exceptional abrasion resistance, tear resistance, and high load-bearing capacity. It also provides excellent shock absorption and noise reduction, protecting the forklift’s structure while creating a more comfortable operating environment.

Reinforced Internal Structure: The wheels typically feature an embedded steel or cast iron core, providing unparalleled compressive strength and structural integrity. This prevents deformation or breakage under extreme heavy-load conditions. The advanced bonding technology between the core and outer material ensures they remain permanently fused.

Precision Bearing System: Equipped with high-quality double-sealed ball bearings or plain bearings. The superior sealing performance effectively prevents the intrusion of dust, debris, and moisture, significantly extending the bearing’s service life. This ensures flexible and smooth wheel rotation with minimal maintenance requirements.

2-Exceptional Product Advantages and Features

Unmatched Durability and Long Service Life:

This is the most outstanding advantage of these load-bearing wheels. Their extreme wear resistance allows them to withstand thousands of hours of repeated use on concrete, epoxy floors, and even rough surfaces. Compared to ordinary wheels, their service life is extended multiple times, significantly reducing replacement frequency and spare parts costs, thereby minimizing the Total Cost of Ownership (TCO).

Remarkable High Load-Bearing Capacity:

Designed specifically for medium to heavy-duty applications of Linde forklifts, a single wheel can bear several tons of weight. With four wheels working in unison, they provide a solid and stable foundation for the entire forklift and its load. Whether moving palletized steel or dense shelving, these wheels handle the task with ease, safety, and reliability.

Comprehensive Floor Protection:

The polyurethane or nylon material is elastic and does not leave black marks, making it extremely friendly to sensitive floors such as epoxy or hardened concrete surfaces. They effectively prevent scratches, dents, or traces, helping maintain a clean and tidy workspace while saving on costly floor repair expenses.

Smooth and Quiet Operation:

The excellent elasticity and shock absorption capabilities effectively absorb impacts and vibrations caused by uneven surfaces. This not only protects the forklift’s precision components (e.g., motors, hydraulic systems) but also significantly reduces operational noise. This creates a more comfortable and focused working environment for operators, enhancing productivity.

Minimal Maintenance Requirements:

"Fit and forget" is a true testament to their reliability. Thanks to the sealed bearings and robust structure, they require almost no additional lubrication or maintenance. This saves valuable maintenance time and labor costs for businesses, allowing the equipment to continue operating and adding value.

3-Application scenarios and cases

1.Logistics warehousing: pallet handling, shelf storage and retrieval, improving product turnover efficiency

2.Industrial manufacturing: Material transportation on production lines, movement of heavy equipment, and adaptation to high-frequency operations

3.Special environment: chemical workshop (corrosion-resistant), cold storage (low-temperature resistant), food factory (clean and dust-free)

4-In-house factory · source manufacturing —— full process control from R&D to delivery production scale

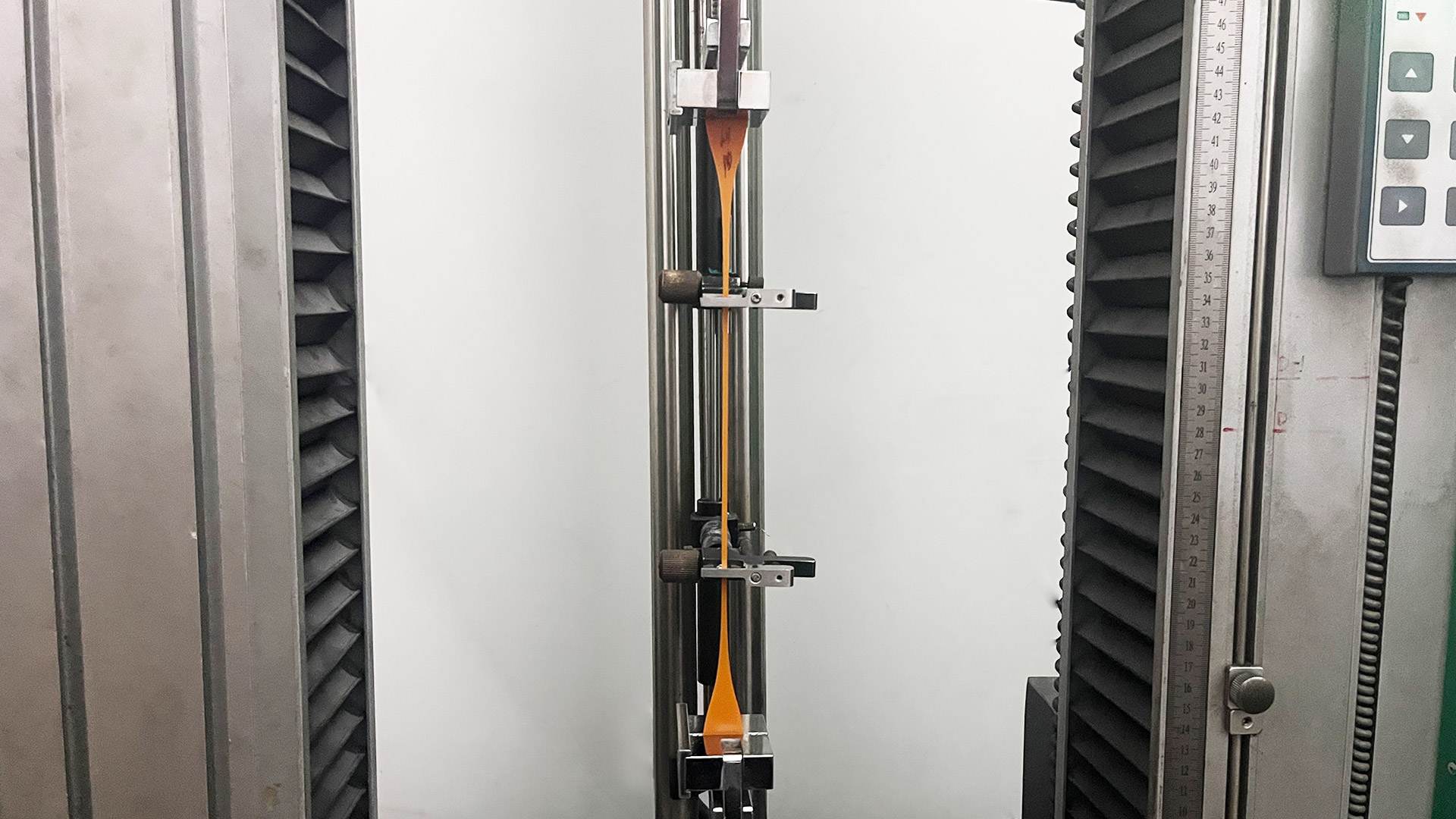

5-Production workshop

|

Linde Wheels |

Diameter,mm |

Height,mm |

Hole diameter,mm |

Depth.mm |

| Driving wheel | 400 | 160 | / | / |

| Driving wheel | 360 | 130 | 90 | / |

| Driving wheel | 350 | 100 | 68 | / |

| Driving wheel | 343 | 135 | 90 | / |

| Driving wheel | 343 | 114 | 90 | / |

| Driving wheel | 285 | 100 | / | / |

| Driving wheel | 254 | 102 | 80 | / |

| Driving wheel | 230 | 90 | / | / |

| Driving wheel | 230 | 90 | 48 | / |

| Driving wheel | 230 | 82 | 45 | / |

| Driving wheel | 230 | 75 | 45 | / |

| Driving wheel | 150 | 48 | 60 | / |

| Driving wheel | 140 | 50 | 20.5 | / |

| Driving wheel | 125 | 40 | / | / |

| Driving wheel | 125 | 26 | / | / |

| Balance wheel | 285 | 100 | / | / |

| Balance wheel | 140 | 55 | 47 | / |

| Balance wheel | 125 | 60 | 47 | / |

| Balance wheel | 125 | 40 | 35 | / |

| Balance wheel | 100 | 40 | 35 | / |

| Bearing wheel | 100 | 40 | 55 | 20.5 |

| Bearing wheel | 85 | 105 | 55 | 22 |

| Bearing wheel | 85 | 100 | 55 | 13 |

| Bearing wheel | 85 | 80 | 55 | 22 |

| Bearing wheel | 85 | 60 | 55 | 22 |

| Bearing wheel | 80 | 55 | 47 | 14 |

|

If you need other specifications, please contact us.

|

||||

Copyright © 2025 Fujian Skystone Intelligent Equipment Co., Ltd. All Rights Reserved.

Network Supported

Network Supported